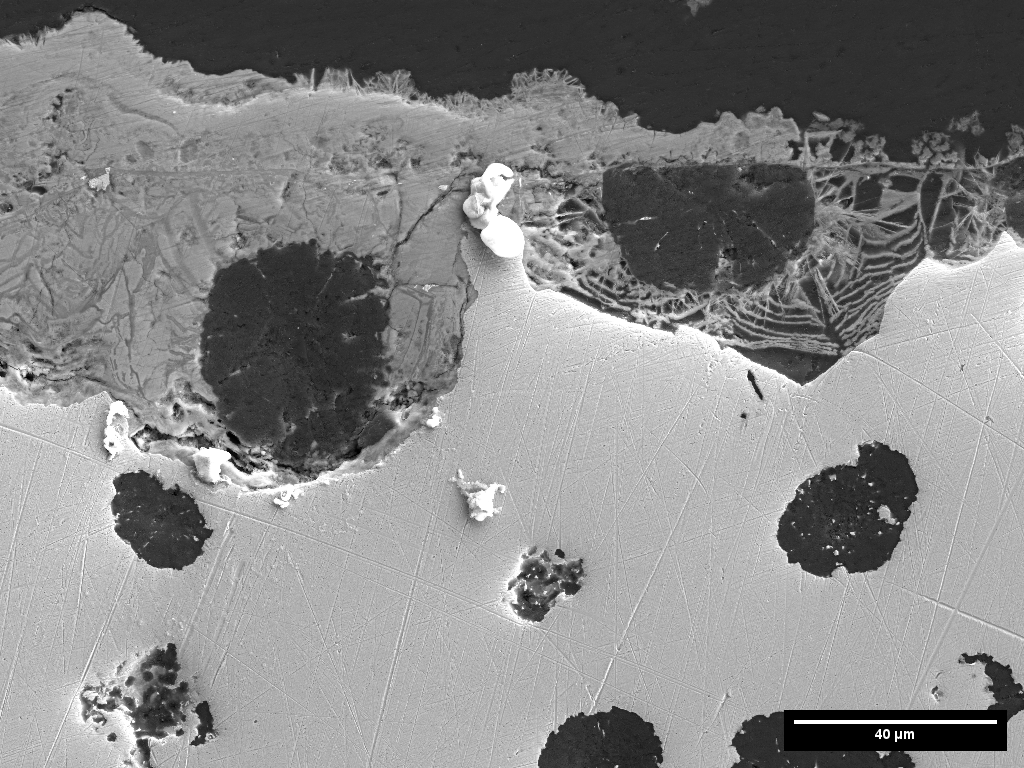

Fig. 1: Corrosion zone in cast iron with spheroidal graphite after storage for 4 months at 60 °C in bentonite suspension [1]

Corrosion mechanisms of potential container materials for the deep geological disposal of high-level radioactive waste (Corrosion mechanisms of potential container materials for the deep geological disposal of high-level radioactive waste)

Project: Corrosion mechanisms of potential container materials for the deep geological disposal of high-level radioactive waste

Profile Corrosion mechanisms of potential container materials for the deep geological disposal of high-level radioactive waste

Project-Lead

Christiane Stephan - Scherb, Louisa Panjiar

Project-Orientation

Forschung

Project-Staff

Publications

[1] Panjiyar, L., Haupt, E. M. I. W., and Stephan-Scherb, C.: Comprehensive insights into corrosion processes of potential canister materials in bentonite suspension at elevated temperature, Third interdisciplinary research symposium on the safety of nuclear disposal practices, Berlin, Germany, 17–19 Sep 2025, safeND2025-28, https://doi.org/10.5194/safend2025-28, 2025.

[1] Panjiyar, L., Haupt, E. M. I. W., and Stephan-Scherb, C.: Comprehensive insights into corrosion processes of potential canister materials in bentonite suspension at elevated temperature, Third interdisciplinary research symposium on the safety of nuclear disposal practices, Berlin, Germany, 17–19 Sep 2025, safeND2025-28, https://doi.org/10.5194/safend2025-28, 2025.